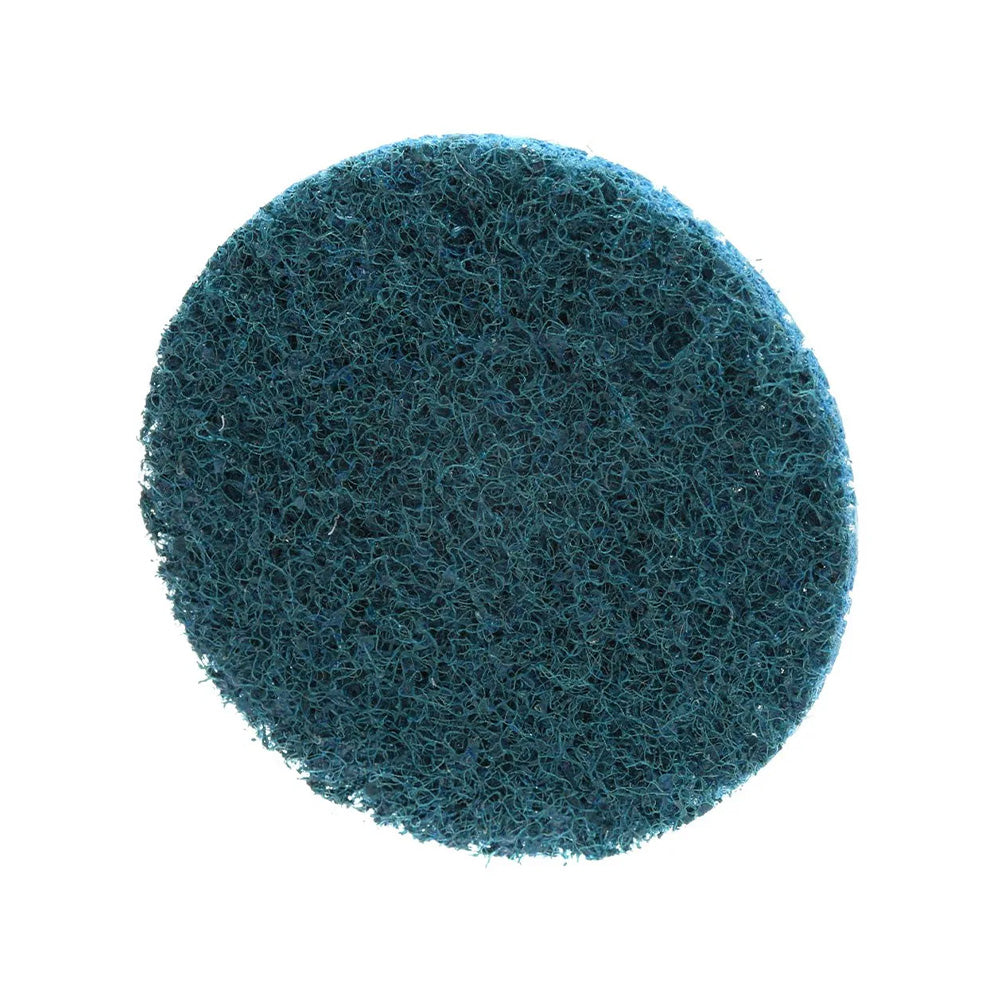

3M 18434 Scotch Brite Roloc Surface Conditioning Disc 19mm TS Very Fine x 50 Pack

Couldn't load pickup availability

3M 18434 Scotch Brite Roloc Surface Conditioning Disc 19mm TS Very Fine x 50 Pack

- Tough non-woven disc aggressively deburrs and finishes

- Conformable, non-woven disc combined with Roloc backing allows for aggressive cutting

- Open-web construction resists loading and runs cool, allowing for consistent finishes

- Convenient 3M Roloc attachment system offers quick and easy disc change-out for multi-step finishing processes

The Scotch-Brite Roloc Surface Conditioning Disc combines 3M's durable, non-woven disc with the efficient 3M Roloc quick-change attachment system for an effective disc that cleans, finishes, blends, and deburrs. Their non-woven fibre construction conforms well to help preserve irregular or contoured surfaces and the Roloc backing supports the disc for aggressive cutting

The open web fibre runs cool and resists loading while the aluminium oxide abrasives provide a high cut rate for consistent finishing. The 3M Roloc attachment system offers quick and easy disc change out, making the Roloc Surface Conditioning Disc ideal for a range of tasks including blending, deburring, and finishing.

3M uses aluminium oxide abrasive in Scotch Brite Roloc Surface Conditioning Discs. Aluminium oxide is a popular choice among industrial professionals because of its cut rate and long life. This mineral is a tough, durable abrasive that self fractures to expose fresh cutting edges in use, whereas traditional abrasives, such as garnet, quickly wear down with use. Due to its high cut rate, hardness, strength and low heat retention, aluminium oxide mineral is widely used in grinding applications in addition to sanding and finishing use. Aluminium oxide is suitable on a wide variety of substrates in both woodworking and metalworking, including ferrous alloys.

3M developed Scotch Brite surface conditioning products with abrasives incorporated into non woven nylon or synthetic fibres. Combining abrasives with the fibres creates an abrasive system that delivers consistent results for the life of the product. The open web material runs cool, reducing the risk of part discoloration and warping. The fibres are load resistant and keep the abrasive minerals cutting at high performance by limiting clogging of the fibres, which also extends the life of the disc.